News & Events

News

Stay updated with the latest news, insights, and developments in engineering biology

24th June 2025

European Circular Bioeconomy Forum – Amsterdam

2 min read time

Continue reading

24th June 2025

European Circular Bioeconomy Forum – Amsterdam

2 min read time

Continue reading

20th May 2025

Business Basics Course

1 min read time

Continue reading

20th May 2025

Business Basics Course

1 min read time

Continue reading

20th May 2024

BBC highlight Modern Synthesis

1 min read time

Continue reading

20th May 2024

BBC highlight Modern Synthesis

1 min read time

Continue reading

11th May 2024

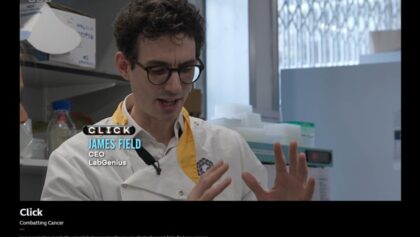

BBC Click Combatting Cancer

1 min read time

Continue reading

11th May 2024

BBC Click Combatting Cancer

1 min read time

Continue reading

19th May 2023

New Government Report

1 min read time

Continue reading

19th May 2023

New Government Report

1 min read time

Continue reading

17th November 2022

SynbiCITE Showcase 2022

1 min read time

Continue reading

17th November 2022

SynbiCITE Showcase 2022

1 min read time

Continue reading

15th September 2020

Measurement for Recovery

2 min read time

Continue reading

15th September 2020

Measurement for Recovery

2 min read time

Continue reading

2nd March 2020

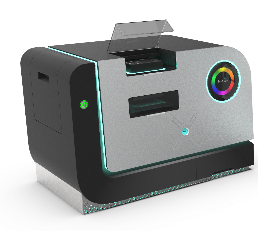

Evonetix raises $30 million USD (£23 million GBP)

4 min read time

Continue reading

2nd March 2020

Evonetix raises $30 million USD (£23 million GBP)

4 min read time

Continue reading

13th January 2020

Evonetix collaborates with imec to scale-up chip-based technology production for third generation DNA synthesis platform

2 min read time

Continue reading

13th January 2020

Evonetix collaborates with imec to scale-up chip-based technology production for third generation DNA synthesis platform

2 min read time

Continue reading

Loading